Okabe Kikai Kogyo Co., Ltd. develops and manufactures rollers for belt conveyors with the slogan “Change, Challenge and Speed”.The product of the material including the roller, use those produced thorough quality control of the original, as a dedicated material.In order to meet various needs, we also support the production of original rollers suitable for the application.

OKABE’S ROLLER SPECIFICATION

OKABE’S ROLLER SPECIFICATION

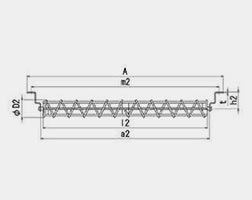

Carrier return roller

Based on the standard of JIS B 8803-1976, we are constantly producing for per belt width 400 ~ 2,000.

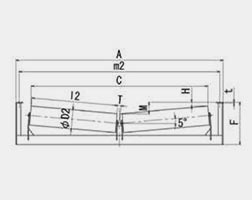

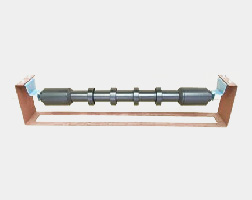

Impact roller

Impact carrier rollers serve as an effective cushion against shocks when large ore, limestone, etc, of comparative lumps fall from the “shoot” onto the conveyor.

Return roller with rubber ring

When transporting adhesive, abrasive and corrosive substances, use a return roller with a ring at regular intervals to prevent roller pipe wear and corrosion caused by deposits on the return side conveyor belt.

Return roller with ceramic ring

When transporting adhesive, abrasive and corrosive substances, use a return roller with a ring at regular intervals to prevent roller pipe wear and corrosion caused by deposits on the return side conveyor belt.

Spiral return roller

Adhesive Use it when transporting goods. The "spiral part" which is twisted to the right from the center and left twist is brought into contact with the belt, which is useful for preventing adhesion of materials on the surface of the roller and removal of deposits on the belt.

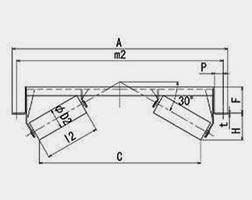

V type return roller.

Tilt type 2 return rollers forward tilt mounting. For prevention of meandering, place it at a ratio of 1 to 5 flat return rollers, especially for high speed conveyors.

Inverted V type return roller

As with V type return, install trough type 2 rollers. Prevent meandering by belt tension and frictional force. Also, since the rollers are brought into contact with the back of the belt, the rollers of the material to be conveyed are brought into contact with each other, so that it is effective in preventing adhesion of materials to be conveyed to the rollers.

Cutout return roller

By reducing the central part of the return roller, the contact area of the belt is reduced, which is effective in preventing falling.

Side roller

Please use it for a large offset of the belt due to unforeseen circumstances and to prevent deviation from the roller.

SC・SR

With the meandering of the belt, the side roller with lever is pushed in the belt advancing direction, and automatic adjustment is performed surely. The roller to be used is compatible with ordinary carriers and return rollers.

TC・TR・TRV

It is an automatic adjustment roller using a special cast iron crown roller. Adjust the belt meandering by rotating the crown roller using the friction resistance with the night belt to the rotational frequency difference of the crown roller.

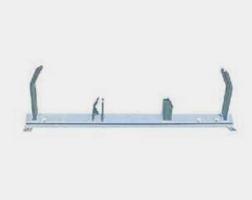

Return bracket with side roller

It is a bracket integrated with return bracket and side roller. It prevents belt ear damage caused by meandering.

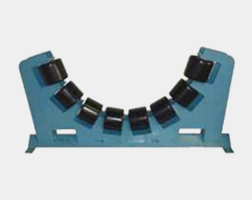

Split type impact frame

By splitting the frame base to the left and right, it is easy to replace the impact roller under the chute.

Variable carrier frame

Carrier trough angle is freely adjustable carrier frame at regular intervals.

Rollerless conversion

Return guard

Tire type impact carrier

(For heavy load)

Roller for abrasion resistant pipe conveyor

It is a wear-resistant roller with ceramics sprayed on the surface of the roller.

With SC ring

The countermeasures against falling-off (countermeasures against falling kicking and falling off of rollers on the belt backing deposit), the effect as a long-life countermeasure due to wear resistance is demonstrated.